In 2017, the market size of China's servo system exceeded 10 billion yuan, an increase of more than 30% from the previous year. The servo businesses of local brands such as Huichuan, Eston, Hechuan, Xinjie and Leisai have made great progress. Inspire the people. However, we should also see that Japanese brands represented by Panasonic, Yaskawa, and Mitsubishi account for 50% of the domestic servo system market share. Siemens, Bosch Rexroth, B&R and other European and American brands have long been in the mid-to-high-end market and are reserved for Chinese local brands. The market share does not exceed 30%. Servo system is the cornerstone of high-end equipment manufacturing. The rapid development of domestic servo system is a necessary condition for practicing the "Made in China 2025" action program. Therefore, it is especially important to build the core competitiveness of domestic servo system manufacturers. The improvement of the competitiveness of China's servo brand must take into account the following two aspects: First, continuous R&D investment, and gradually break down technical barriers; Second, improve the support of the industrial chain, it is difficult for a woman to be a leader, and only get rid of the foreign brands in the supply chain. In order to make great achievements.

The IGBT is called the "CPU" of power electronics and is the core component of the servo driver. At present, IGBT single tubes and modules are used in servo products, and more than 90% rely on foreign imports. Mitsubishi, ON Semiconductor, Fuji, ST and Infineon are the current mainstream suppliers. Imported IGBTs are not only expensive, but also often have tight supply problems, which greatly restricts the development of domestic servo brands. Fortunately, the quality of domestic IGBT products is increasing, and it has the ability to supply in batches. Shenzhen Core Energy Semiconductor Technology Co., Ltd. is the leader in the domestic IGBT industry In particular, IPM products have formed the most complete product sequence in China.

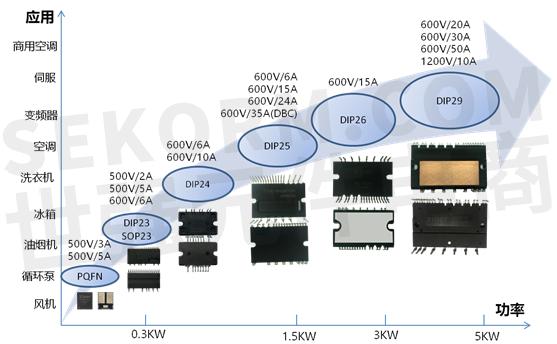

The above picture shows the product sequence of Core IPM. There are more than 20 models in 7 packages below 5KW for customers to choose, covering consumer fans, inverter appliances, servo drives, commercial air conditioners and other markets. The DIP29 product is a pure industrial IPM product, launched It has won the love of servo drive customers, solved the customer's several pain points, and became a veritable star product. So what are the advantages of the core DIP29 IPM?

1. Fully compatible with imported brands, and the product range is complete, which can meet the needs of customers with different power levels.

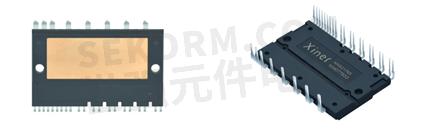

The core energy DIP29 IPM hardware is fully compatible with an imported brand Mini series products, which can be directly replaced without changing the board. The package has 6 products for customers to choose, easy to expand the power segment, easy to design the customer series products, greatly reducing the development cycle and design investment.

2, heat conduction and insulation performance are stronger

The thermal conductivity of core IPM products is better, mainly determined by the following two points:

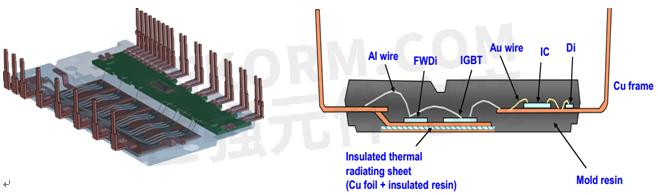

First, the core energy DIP29 adopts the DBC process (as shown in the left figure above), which is different from the lead frame of the competing product + the high thermal conductive insulating resin + copper skin process. The thermal conductivity of ceramics in DBC is above 20, while the thermal conductivity of high thermal conductivity insulating resins is 4-5. At the same time, the insulation performance of DBC is far superior to that of resin (the thermal resistance of alumina ceramic insulation in DBC is 40). KV/mm, high thermal conductivity insulating resin is 17KV/mm).

Second, the core can use vacuum reflow soldering to solder the wafer to the DBC. The void ratio can be controlled to about 1%, which is more conducive to the diffusion of heat. The competing product is ordinary reflow soldering, plus the adhesion between the copper foil and the resin. With the process, the overall void rate is much larger.

3, the protection function is more complete.

Core energy DIP29 built-in imported SOI process driver IC, representing the most advanced driving level in the industry, anti-interference ability and anti-negative capacity is super strong; with dead zone interlocking ability, system security is higher; and short circuit protection 6 The IGBTs can be turned off at the same time, while the competing products only close the 3 lower arms.

·Overcurrent protection (OCP)

· Desaturation Protection (DESAT)

· Undervoltage lockout protection (UVLO)

· Configurable status indication (fault), enable and disable

4, system security is more flexible, flexible customized service.

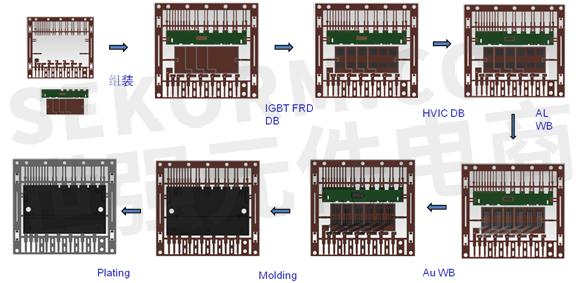

DIP29 adopts DBC+PCB technology. DBC and PCB are mature accessories. According to different needs of customers, driver chips and power devices can be customized to increase product added value. Compared with the lead frame, the mold opening cost is greatly reduced, the customization cost is low, and the cycle is short.

5, technical support to force

Core Energy's application engineers have more than 12 years of experience in IGBT applications, and South China and East China are staffed to provide customers with technical support in place, allowing customers to use more peace of mind.

With excellent products and services, Core has gradually won the recognition of customers in the industrial control market and contributed its strength to “China Zhizhi”. At present, the challenges and opportunities of the servo market coexist. Despite the strict barriers, the pace of China's servo enterprise brand will not stop. Shenzhen Core can adhere to the customer-centered, and hopes to further cooperate with domestic system application companies to break the foreign monopoly and form a monopoly. Belong to the real combat power of domestic system manufacturers!